Nistune has recently introduced a large expansion to their software and firmware called the Feature Pack. It basically brings a few often-requested features to the ECU which are otherwise not possible or available with the stock ECU. These are:

- Total Injection Multiplier, separate from the K-value.

- Flex Fuel Support

- Launch Control

I was lucky enough to run a pre-release version of this on my own Z32, and I’m still in the process of testing and playing with these features, but I wanted to documented this along the way. Some of this is out of chronological order, but still presented in a way that makes sense.

In this article, I installed the Nistune Type 2 Daughterboard into a socketed ECU, along with the Nistune Flex Board.

The donor ECU was actually one I stumbled on as a core a while back, but I wasn’t comfortable sending it out to a customer as it was missing the diagnostics LED, which I didn’t really need anyway. So I started by disassembling my old ECU, so I could remove the Nistune Daughterboard and ribbon cable.

|

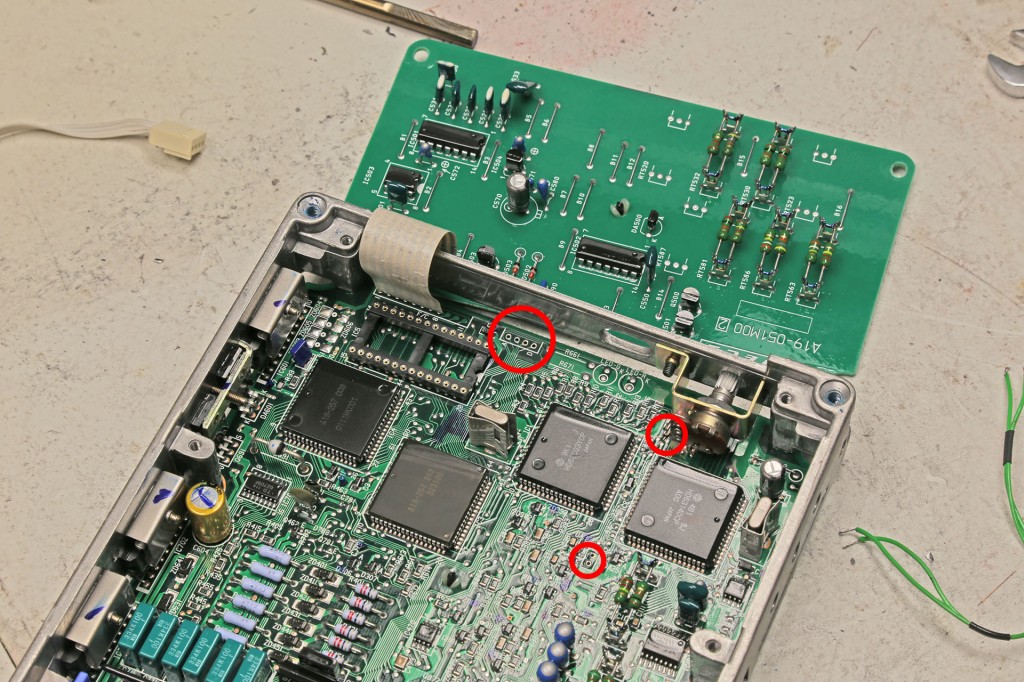

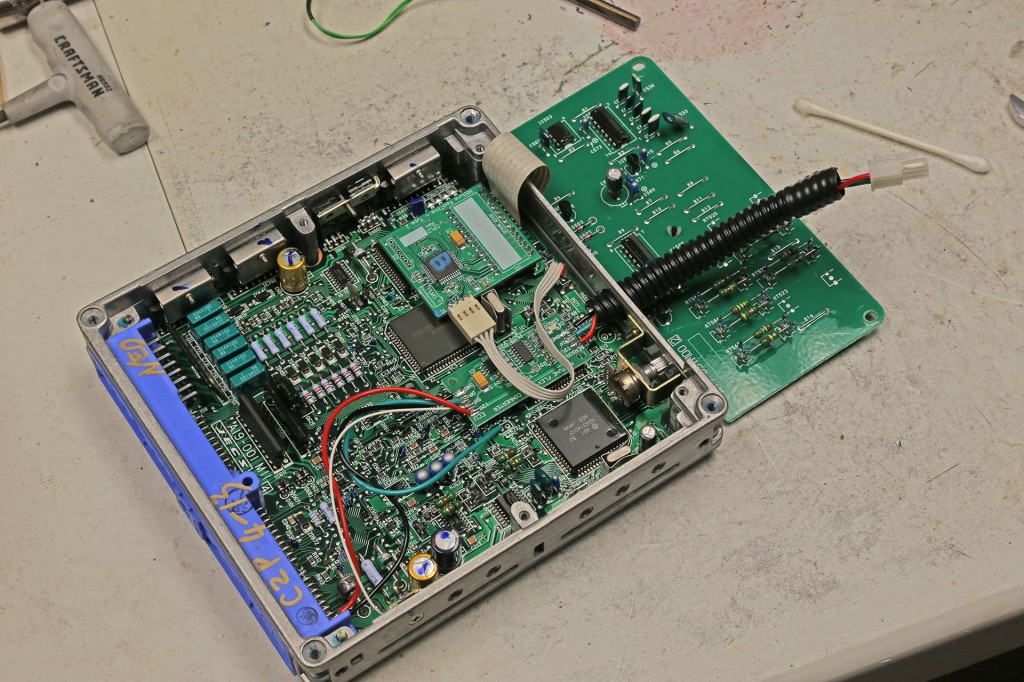

Here is the new ECU everything will go into. It’s a minty fresh JDM remanufactured ECU, with the new-style knock board.

After getting it apart, I desoldered the 2-wire leads for the diagnostics selector, as the Flex Board would take its place. I also removed the solder from the 4-pin header connector which is used by the Nistune Daughterboard.

The upper circle is where the ribbon cable installs on the Nistune Daughterboard, the two on the right are where the diagnostics selector wires used to connect.

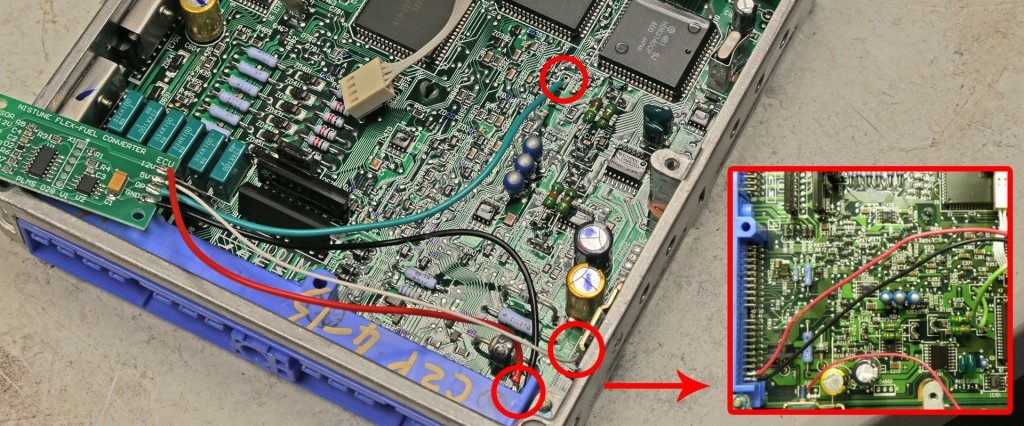

The Flex Board has four wires which need to be soldered to the ECU.

- Green – Connects to one of the pins used for the diagnostics select, the one closest to the blue ECU connector.

- White – Connects to the center pin on the component towards the bottom corner by the ECU connector. It needs to go to the middle pin, labeled Q101.

- Black – Connects to the outer-most upper pin on the ECU connector.

- Red – Connects directly adjacent to the black wire above.

The Flex Board can then be mounted into the ECU however you like. As this ECU did not have a diagnostics LED, I opted to mount it right in front of the opening for the LED, giving a perfect location for the harness to run through. On future ECUs, I will be removing the diagnostics selector and using a rubber stress relief at that port.

Finally, I ran a segment of flexible loom through the opening, and then ran the subharness pigtail through the loom before soldering directly to the Flex Board. Here is the pinout for those wires:

- Black – GND

- Green – IP

- Red – 12V

At this point, I had already reinstalled the Nistune Daughterboard’s 4-pin ribbon cable.

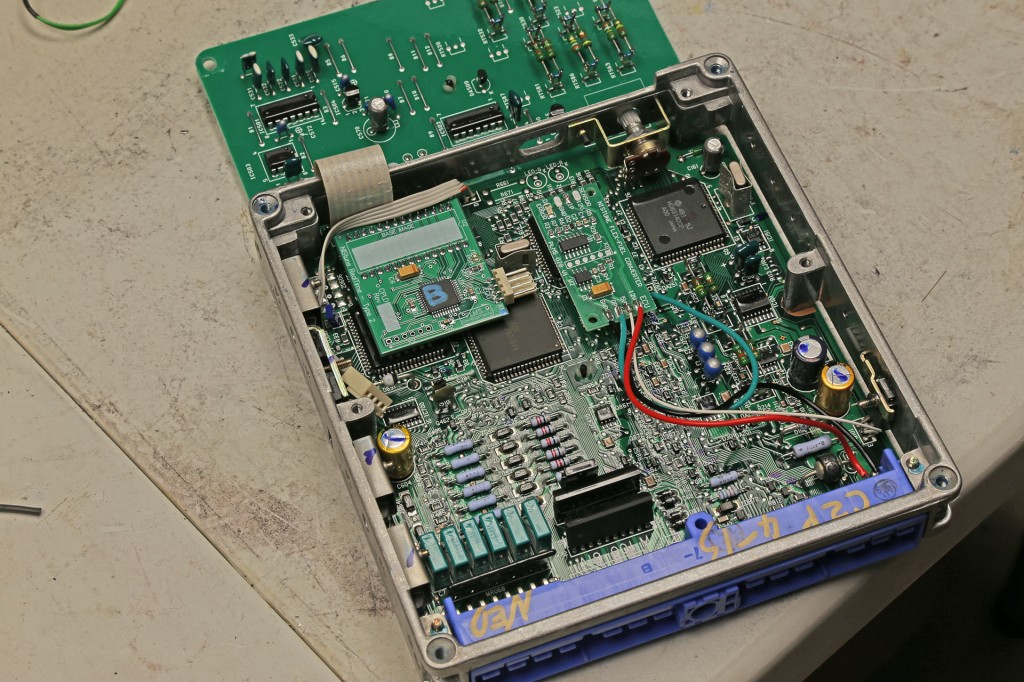

Here the ECU is basically done. I also ended up adding some foam tape to the ribbon cable for the knock board, to prevent the pins on the daughterboard from coming rubbing through. Then buttoned it all up.

With the flex board (and sensor) now installed, the ECU can read the ethanol content in the fuel, and it can also be displayed via the Knock Warning Panel in Nistune. Note that you’ll want to install the content sensor prior to installing the flex board and enabling Flex Fuel support, as the ECU will treat the output from the flex board as being used for the diagnostics selector otherwise.

In most states, normal pump gas contains up to 10% ethanol, which allows us to confirm the flex sensor & board is working.

To be continued…

2014. continuation??

can you make me one of these ecus? 94 na being converted to na-TT

looking for that flexfuel setup:

https://conceptzperformance.com/blog/nistune-feature-pack-part-1/

thanks in advance

phil

phillip.olsson@gmail.com

p.s. help me make my baby finally run like the true beast she is!

https://scontent.ftpa1-2.fna.fbcdn.net/v/t1.0-9/13094392_619954914818166_4371487835204617310_n.jpg?oh=149d8ccb879b9586ee650b3c078977dd&oe=5A87AC05

Not with a 94 NA ECU, you could use any 8-bit ECU which is going to be 90-92 for the NA though