Idle Control

The Z32 has a somewhat complicated idle control system. Z32s are notorious for poor idle, as any minor running issue tends to manifest itself quite heavily when the engine is idling. This is compounded by the fact that, because the Z32 has such a dizzying array of sensors compared to most cars from the era, owners are often unaware of a sensor being incorrectly set or malfunctioning all together.

Components

There are three physical components that are strictly for the idle control of the car.

- Auxiliary Air Controller (AAC)

- Fast Idle Control Device (FICD)

- Air Regulator

The AAC and FICD are both solenoids that help make up the Idle Air Control Valve (IACV). The IACV also contains an adjustment screw for setting the base idle. The AAC housing receives air from the pipe connecting to the driver's side accordion pipe, and/or from the balance tube, through the air regulator.

Auxiliary Air Controller

The AAC is the primary controller for maintaining idle speed. It is a simple ON/OFF solenoid, and the ECU controls it with a varying pulsewidth, similar to a fuel injector. The higher the pulsewidth, the longer the solenoid is open, allowing more air to enter and the idle to raise. When the pulsewidth is lower, it's open less, and less air enters, lowering the idle.

Fast Idle Control Device

The FICD is a secondary solenoid. When it opens, it allows a specified amount of additional air to enter. It's purpose is to raise the idle immediately when turning on the A/C compressor, or when the power steering pump is under heavy load (turning the steering wheel while idling, for example). The additional idle speed is to help the engine compensate for the added load of these accessories, rather than simply stalling out.

Air Regulator

The Air Regulator is a shutter valve which uses a bimetal spiral spring to open or close. When the spring is cold, the valve is fully open. When the car is turned on, voltage is applied to the bimetal, causing it to heat up. As it heats up, the valve gradually closes. The Air Regulator's purpose is to raise the idle speed when the engine is cold.

Some advocate removing the Air Regulator and capping it's ports, as the ECU will automatically raise the idle speed while cold through the AAC, obfuscating the Air Regulator altogether.

Base Idle Screw

The Base Idle Screw is a small flat-head screw built into the IACV housing. It allows a user-defined amount of air to enter the IACV, regardless of the condition of any other sensors. Besides the ECU's control of the AAC sometimes takes a few seconds to react to quick, unexpected changes in throttle position and engine load, the base idle screw is necessary for maintaining a small amount of air through the IACV, to prevent the engine from stalling before the AAC can "catch" it.

Note: Some erroneously believe that the base idle screw is like that on a carburetor, which allows the user to define the idle speed outright. This is incorrect, and the base idle screw's only purpose is to provide a base volume of auxiliary idle air, while the above components add to that volume to maintain the idle speed.

Throttle Position Sensor

The TPS's internal hard idle switch is used to tell the ECU when the throttle is fully closed, so it can attempt to make the engine idle. If the TPS is set incorrectly and the hard idle switch isn't on when the throttle is closed, the car will idle very high. For more info, see the Throttle Position Sensor article.

Setting the Base Idle

The idle speed isn't user-defined, but it is necessary to make sure the conditions are right for the ECU to control the idle speed.

- Fully warm up the car. Drive it around the block if necessary.

- Disconnect the electrical connector for the AAC valve.

- Turn the Base Idle Screw clockwise until the idle drops to about 650 RPM.

- Reconnect the AAC valve's connector.

- The idle should quickly raise, then gradually settle down to about 750 RPM.

Troubleshooting

Of course, nothing is that simple, right? Follow these steps to try to narrow down problems while setting the idle speed.

Engine stalls when disconnecting AAC

This happens if the base idle screw is turned in too tightly, restricting the amount of auxiliary air it receives. Without the AAC operating, there's not enough air to maintain idle. Turn the base idle screw counterclockwise a few turns, then attempt to set the base idle again.

Idle speed will not lower

If, when you disconnect the AAC connector (be sure you're not removing the FICD connector), you are unable to lower the idle speed by turning the screw in, then you have a vacuum leak, from the throttle bodies-forward. This could also mean that the throttle bodies themselves are sticky or improperly adjusted and are no longer closing fully, allowing too much air to enter.

Idle speed too high with AAC connected

You disconnect the AAC, and the idle speed drops down where it should be, perhaps even too far (see "engine stalls..." above). But when you reconnect the AAC, the idle shoots up to 1200, or even 1800 RPM, and does not come back down.

This indicates a problem with the Throttle Position Sensor. Most likely, it's set incorrectly, and the hard idle switch is not turning ON when the throttle is closed. Because the idle switch is not turned on, the ECU thinks the throttle is open, and opens the AAC to allow more air to enter the engine. Set the TPS and try setting the base idle again.

It is also possible that the coolant temp sensor is malfunctioning and reporting an incorrect temperature to the ECU, causing the idle speed to raise.

ECU Control

The ECU looks at two main parameters to control the engine idle speed.

- TPS Sensor hard idle switch (should be ON to enter idle mode).

- Neutral position switch (automatic ECUs only).

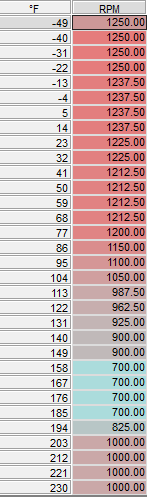

- Target idle RPM vs engine temperature. This is a table stored on the ECU's EPROM which is exactly what it sounds like. It tells the ECU what to set the idle for depending on the engine temperature.

In general, disconnecting the AAC is a quick way to determine if your idle problems are being caused by a physical problem (such as a vacuum leak), or an electrical problem (ie the ECU raising the idle because the TPS is set incorrectly).