Throttle Position Sensor

The Throttle Position Sensor or TPS is an electrical sensor that tells the ECU how far open or closed the throttle body of a car is. In a car with cable-actuated throttles (as opposed to "drive-by-wire"), the accelerator pedal physically opens and closes the throttle. However, because cars utilizing Electronic Fuel Injection change various engine-controlling parameters for different driving situations, it is necessary for the ECU to be able to read the open or closed position of the throttle.

Contents

On the Z32

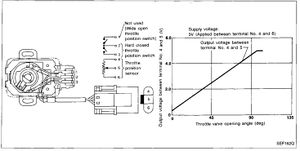

The Z32's throttle position sensor is actually two devices in one housing. Two parts that make it up are the Throttle Sensor and Hard Idle Switch. The Throttle Sensor uses the oval-shaped gray connector on the pigtail, while the Hard Idle Switch uses the three-pinned square connector on the front of the unit. The Throttle Sensor returns a specific voltage, ranging between approx 0.4V DC to approx 5.0V DC, which is used to indicate exactly how far open the throttle is (with ~0.4V being totally closed and ~5V being totally open). The Hard Idle Switch is an ON/OFF switch that turns on to tell the ECU that the throttle is completely closed and to enter "idle mode."Some Z32 TPSs also include a Wide-Open Throttle Switch. It is functionally identical to the Hard Idle Switch, with the sole exception being that it turns on when the throttle is fully opened (rather than fully closed). However, this switch is not used by the Z32 (automatic Zs use a "kickdown" switch located under the gas pedal).

Setting the TPS

An incorrectly adjusted TPS will cause the car to buck or briefly stall when coming off idle, or make the car idle high (around 1500 RPM usually). It's vital that the TPS is set correctly.

For your TPS to be set correctly, the following conditions must all be simultaneously true.

- The throttle bodies should be closed all the way. Removing the intake pipes allows you to see if they are completely closed. With the throttle closed, you should be able to see a port (one on each throttle) on the bottom of the throttle chamber. These ports lead to vacuum nipples on the undersides of the throttle chambers. If the butterfly valve is slightly open, it usually obscures the ports.

- The Throttle Sensor must read between 0.4v and 0.5v.

- The Hard Idle Switch should be "ON."

Consult Interface

The best way to set the TPS is to use a Consult interface such as Nissan DataScan or conzult. This allows you to quickly and easily see both the voltage of the Throttle Sensor and condition (ON or OFF) of the Hard Idle Switch.

After loosening the two small screws holding the TPS to the driver's side throttle body, rotating it will change the states of the two sensors. Rotating it clockwise lowers the Throttle Sensor's voltage, and rotating it counter-clockwise increases it.

There is a "sweet spot" found while rotating the TPS where the Hard Idle Switch will turn on WHILE the Throttle Sensor reads between .4v and .5v. A common method of failure for the TPS appears where these two requirements cannot be met at the same time. That is, it can be set to show voltage between .4v and .5v, but the Hard Idle Switch shows off. If it's set to a position where the Hard Idle Switch turns on, the Throttle Sensor won't be in the proper voltage range (often around .3v). Owners will often set their TPSs to in the ~.4v-.5v range, but without the Hard Idle Switch being on, the car will idle high (between 1500RPM and 2000RPM).

If you're unable to get the TPS voltage and hard idle switch to their "sweet spot," try this:

- Rotate the TPS so that the TPS voltage is reading between 0.4 to 0.5v.

- Unplug the gray oval TPS connector for several seconds. You should be able to see the voltage (as displayed via consult) rise. After about ~8 seconds, the hard idle switch should display "on"

- Reconnect the gray oval TPS connector.

Another, less common method of failure is one where the Throttle Sensor "track" becomes dirty. This causes the voltage to have "dead spots", which can present itself as hesitation or bucking while driving.

Volt Meter

The TPS can also be adjusted and set with basic tools.

Tools Required

- Philps screwdriver and/or 7mm thin-wall socket.

- Multimeter

Original writeup from this thread.

Hard Idle Switch

- Remove the front connector of the TPS (for the hard idle switch).

- Check the continuity across pins A and B. There should be continuity between the pins when the throttle is closed, and no continuity when the throttle is opened.

Position Sensor

- Disconnect the gray oval connector.

- Turn the key to ON. Don't start the car.

- The following voltage readings should be true. This will verify the TPS is receiving power correctly.

- Pin A (black wire) to ground should be 0V.

- Pin B (orange/blue wire) should be 5V.

- Remove the key from the ignition.

- The following resistance readings should be true. This will verify the TPS is smoothly adjusting its output value.

- Pin C (black wire) to pin E (red wire) should be about 9,000 ohms.

- Pin C (black wire) to pin D (white wire) should be 1,000 ohms. If you slowly open the throttle, this resistance should climb to about 9,000 ohms.

- Plug the TPS (gray oval) connector back in.

- Use a small strip of solid (not stranded) wire and insert it into the back of the connector where the white wire is connected on the TPS side. Insert it far enough to make contact with the electrical pin inside.

- A paperclip works well, too.

- Turn the key to ON. Don't start the car.

- Measure the voltage between the wire you inserted and ground (the body of the plenum will work). The voltage should be between 0.4v and 0.5v. As you open the throttle, it should go up to between 4V and 5V.

Adjustment

If your hard idle switch isn't showing ON with the throttle closed, or the position sensor isn't in the correct voltage range, it is necessary to adjust your TPS.

- Leaving the hard idle switch disconnected, loosen the TPS bolts (2x 7mm). Do not remove them, and be careful not to strip them if you're trying with a philips.

- Continue to read the resistance across pins A and B (as seen in the Hard Idle Switch section). Rotate the TPS so that the switch just turns on (continuity exists).

- Gently snug at least one of the TPS bolts down.

- Reading the voltage across the inserted wire from the Position Sensor section, ensure the voltage is between 0.4V and 0.5V.

- If any adjustments are made to get the position switch into the correct voltage range, repeat step 2 to ensure the hard idle switch is still showing ON with the throttle closed.

- If you're unable to get the TPS voltage and hard idle switch to their "sweet spot," try this:

- Rotate the TPS so that the TPS voltage is reading between 0.4 to 0.5v.

- Unplug the gray oval TPS connector for several seconds. You should be able to see the voltage (as displayed via consult) rise. After about ~8 seconds, the hard idle switch should display "on"

- Reconnect the gray oval TPS connector.

- If you're unable to get the TPS voltage and hard idle switch to their "sweet spot," try this:

For your TPS to be set correctly, the following conditions must all be simultaneously true.

- The throttle bodies should be closed all the way. Removing the intake pipes allows you to see if they are completely closed. With the throttle closed, you should be able to see a port (one on each throttle) on the bottom of the throttle chamber. These ports lead to vacuum nipples on the undersides of the throttle chambers. If the butterfly valve is slightly open, it usually obscures the ports.

- The Throttle Sensor must read between 0.4v and 0.5v.

- The Hard Idle Switch should be "ON."

There is a "sweet spot" found while rotating the TPS where the Hard Idle Switch will turn on WHILE the Throttle Sensor reads between 0.4v and 0.5v. If this cannot be achieved, the sensor is bad and must be replaced.