Paragon

Track

Performance

Big

Brake

Kit

(PA015

/

PA035

6

piston)

- Nissan

Skyline

R32

/

R33

(all

trims,

incl.

GT-R)

Front

Paragon

Track

Performance

Big

Brake

Kits

offer

superior

braking

performance

specifically

designed

for

track

day

enthusiasts.

Come

complete

with

every

component

required

to

upgrade

your

brake

system.

Developed

with

performance,

quality,

and

longevity

in

mind,

only

the

finest

materials/components

were

used

to

ensure

the

brake

kits

to

perform

and

last

under

both

street

and

track

conditions.

-

Features

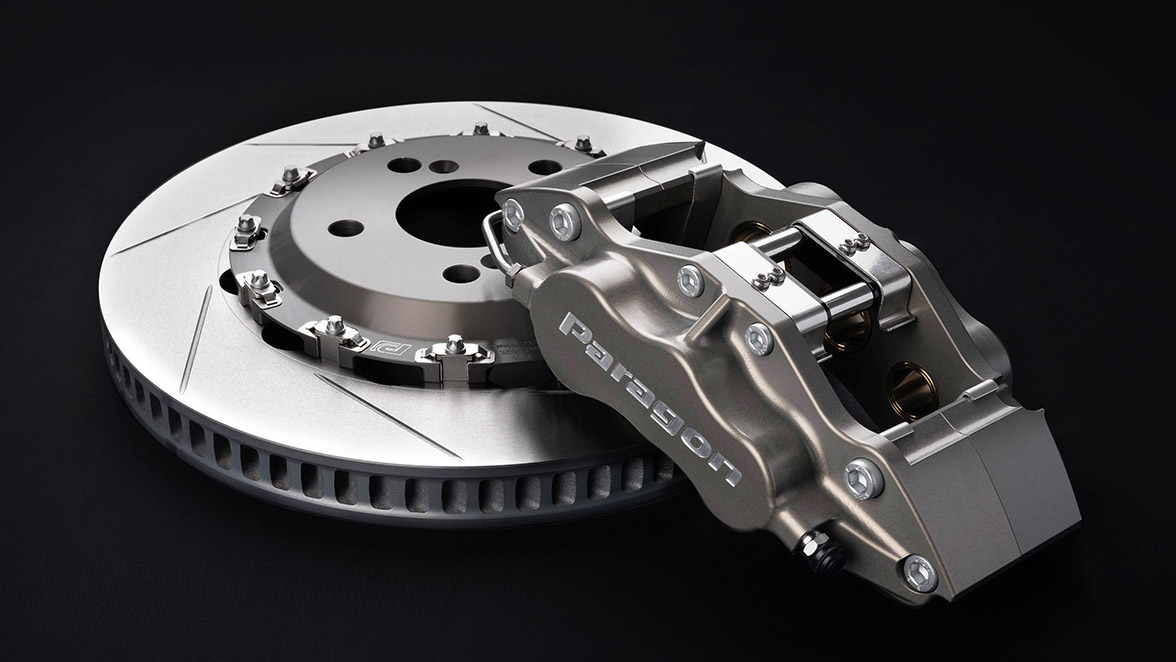

Paragon

PA015

/

PA035

6

piston

calipers *Only

difference

between

the

PA015

and

PA035

calipers

is

the

maximum

rotor

size

they

can

accommodate

-

Fully-floating

2-piece

rotors,

with

directional

ventilation

vanes

for

optimal

cooling

performance.

Runs

up

to

30%

cooler

than

O.E.

rotors

-

Hard

anodized

calipers

and

rotor

hats

for

increased

resistance

to

wear

and

discoloration

under

extreme

track

conditions

-

Piston

sizes

optimized

for

each

application.

Designed

to

work

flawlessly

with

OEM

ABS

and

brake

master

cylinder.

Compatible

with

OEM

rear

brakes

-

Confidence-inspiring

heat

resistance

during

extended

sessions.

Optimum

bite,

modulation

characteristics,

thermal

stability,

and

durability

-

Recommended

usage:

Street

/

Track

-

Complete

pre-assembled

axle

set

Includes:

-

One

pair

of

Paragon

PA015

/

PA035

6

piston

calipers

-

One

pair

of

Paragon

fully-floating

2-piece

rotor

assemblies

with

hard

anodized

6061-T6

aerospace

grade

aluminum

hats,

stainless

steel

bobbins,

and

anti-rattle

clips

-

One

set

of

Paragon

P3

“Street/Track”

semi-metallic

brake

pads

(manufactured

by

Winmax

Japan,

other

compounds

available

at

additional

cost)

-

One

pair

of

caliper

mounting

brackets

and

all

necessary

hardware

-

One

pair

of

Goodridge

DOT

approved

stainless

steel

braided

brake

lines

-

One

set

of

caliper

anti

rattle

clips

-

Detailed

installation

manual

***Please

verify

wheel

fitment

/

clearance

before

ordering.

All

Paragon

big

brake

kits

are

custom

made/packaged

to

order,

and

cannot

be

returned

due

to

wheel

fitment

issues.

Wheel

Fitment

Template

Download

(PDF):

343x32mm

/

355x32mm

/

378x36mm

>

How

to

use

the

wheel

fitment

template

(PDF)

**343mm

brake

kits

generally

require

17"

or

larger

wheels,

355mm

brake

kits

generally

require

18"

or

larger

wheels,

while

378mm

brake

kits

generally

require

18"/19"

or

larger

wheels. Fitment

varies

due

to

different

specs

/

wheel

design.

Verify

fitment

with

wheel

fitment

template.

Application:

-

1989-1994

Nissan

Skyline

R32

(all

trims,

incl.

GT-R)

Front

-

1993-1998

Nissan

Skyline

R33

(all

trims,

incl.

GT-R)

Front

Kit

Number:

-

PBK.02.080.343.320.TL.01.02.Px.F

(343x32mm

Rotor)

-

PBK.02.080.355.320.TL.01.02.Px.F

(355x32mm

Rotor)

-

PBK.05.080.378.360.TL.01.02.Px.F

(378x36mm

Rotor)

PA015

/

PA035

6

Piston

Calipers

-

CNC

machined

from

billet

6061-T6

aluminum

-

Outstanding

rigidity.

Reduces

compliance

which

allow

for

a

consistent

pedal

feel,

and

improves

responsiveness/modulation

characteristics

-

Titanium

nitride

(TiN)

coated

pistons.

Improve

durability

and

extend

service

intervals

by

protecting

the

sliding

surfaces

of

the

pistons.

Allow

smooth

piston

travel

-

Stainless

steel

pistons

can

act

as

an

effective

thermal

barrier

due

to

the

lower

thermal

conductivity

vs.

aluminum

pistons,

which

help

prevent

brake

fluid

boiling

and

brake

fade.

Extra

machining

is

done

to

minimize

contact

with

the

pads

-

Staggered

piston

bore

sizes

for

improved

brake

balance

and

even

pad

wear

-

High

temperature

piston

seals

and

internal

dust

seals

are

utilized

to

withstand

the

heat

generated

under

harsh

track

conditions

and

extend

caliper

service

life.

Internal

dust

seals

are

able

to

offer

protection

against

debris/contaminants

and

will

not

melt

as

easily

as

the

external

dust

boots

that

are

commonly

used

on

OEM

calipers

-

Hard

anodized

finish

for

improved

wear

resistance.

Unlike

painted/powder

coated

calipers,

hard

anodized

finish

will

not

deteriorate

under

extreme

heat

-

Replaceable

stainless

steel

abutment

plates

to

allow

smooth

braking

action

and

prevent

wear

on

the

caliper

body

-

Strong,

yet

lightweight.

Each

caliper

weighs

6.5

lbs

(without

pads)

-

Optional

anti-knockback

springs

-

Stainless

steel

bleed

screws

and

crossover

pipes

Floating

2-piece

Rotors

-

Floating

2-piece

design

allows

thermal

expansion

of

the

rotor

while

minimizing

deformation

and

ensuring

the

rotor

is

self-centered

with

the

pads

-

Superior

braking

and

cooling

performance

-

Features

72

directional

ventilation

vanes

to

create

suction,

turbulence,

and

guides

cool

air

through

the

rotor

for

improved

heat

dissipation

and

increased

resistance

to

cracking

-

Made

of

CM-250

special

formulated

high

carbon

alloy

cast

iron.

Allows

for

an

optimal

bite,

thermal

characteristics,

high-temperature

strength,

and

durability

-

Heat

treated

to

release

stress

in

the

rotor

to

avoid

deformation

and

vibration

-

State-of-the-art

CBN

surface

machining

to

ensure

better

break-in

with

new

brake

pads

-

Excellent

thermal

capacity. Allows

the

rotors

to

absorb

and

dissipate

heat

more

efficiently

and

help

reduce

chance

of

brake

fade

-

Replacement

rotor

rings

available

at

competitive

price

Curved

Directional

Ventilation

Vanes

Features

72

directional

ventilation

vanes

to

create

suction

and

turbulence,

and

guide

cool

air

through

the

rotor

to

achieve

better

heat

dissipation

and

increased

resistance

to

cracking

under

harsh

track

conditions.

Each

rotor

is

left

or

right

side

specific,

and

the

ventilation

vanes

are

optimized

to

spin

in

a

particular

direction

to

pump

the

maximum

amount

of

cool

air

through

the

rotor.

This

design

allows

the

rotor

to

run

up

to

30%

cooler

than

O.E.

rotors

and

increases

cooling

efficiency

by

up

to

30%

over

standard

1-piece

units.

Brake

fade

and

judder

are

minimized

during

extended

sessions.

This

means

the

brake

system

can

withstand

heavier

track

usage

and

provide

consistent

braking

performance

lap

after

lap.

Slotted

Friction

Face

Slotted

rotor

face

pattern

improves

brake

consistency

by

constantly

cleaning

the

contact

surface

and

dissipate

heat

generated,

and

gases

released

when

the

pads

come

into

contact

with

the

rotors.

Slotted

rotors

have

a

superior

advantage

over

blank

rotors

in

wet

or

raining

conditions

by

preventing

water

films

to

form

between

the

brake

pad

and

rotor

surface.

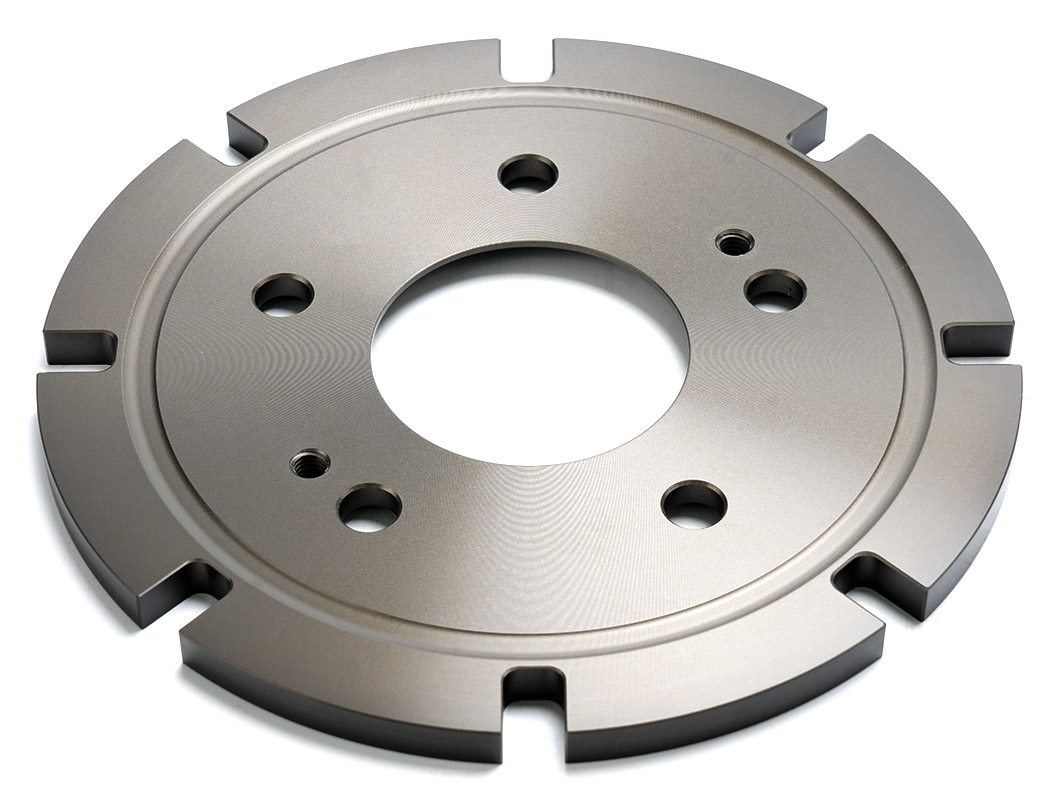

Hard

Anodized

Aluminum

Hats

-

CNC

machined

from

lightweight

6061-T6

aerospace

grade

aluminum

-

Unsprung

weight

reduction

-

High

strength

and

durability

-

Hard

anodized

to

increase

resistance

to

wear,

corrosion,

and

discoloration

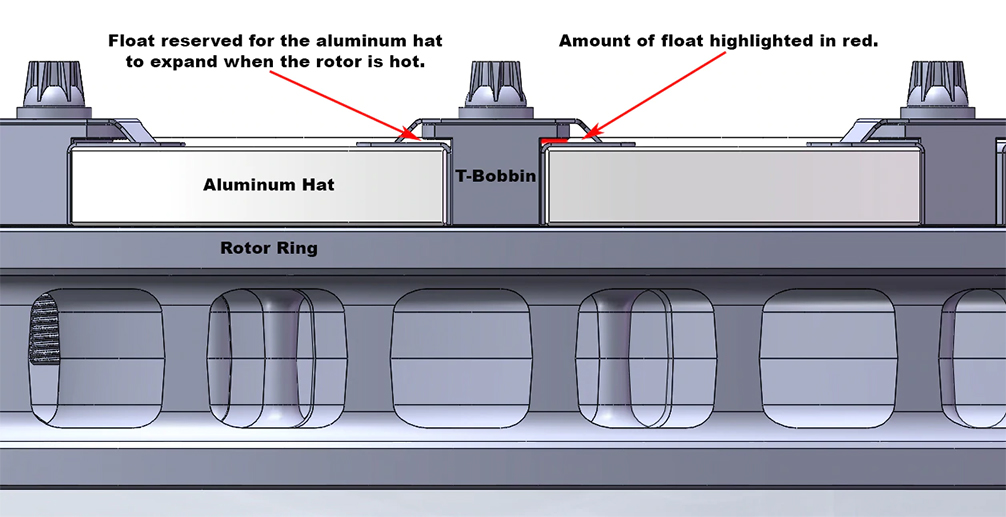

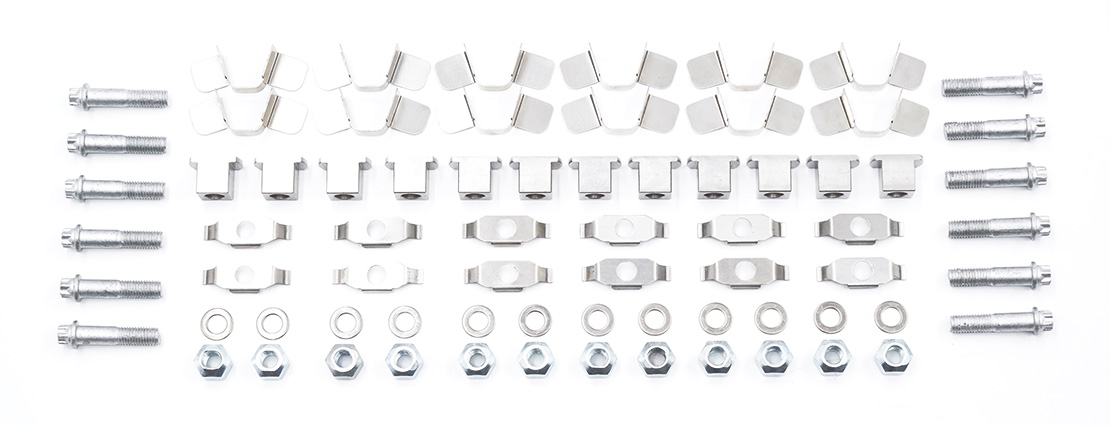

Floating

Bobbins

&

Mounting

System

Utilizes

T-Bobbin

rotor

to

hat

mounting

system

to

allow

"float"

in

both

radial

and

axial

directions,

and

minimize

brake

judder.

The

high

quality

stainless

steel

hardware

are

corrosion

resistant

which

allows

secure

mounting,

and

smooth

expansion

and

contraction

throughout

heat

cycles.

Anti

wear

clips

(McLaren

spring

clips)

are

utilized

to

slightly

pre-load

the

rotor

assembly

and

minimize

rattling

noise.

Caliper

Mounting

Brackets

CNC

machined

caliper

mounting

brackets

to

ensure

superior

strength,

durability,

and

secure

mounting

of

calipers

to

knuckles.

Paragon

Brake

Pads

-

Manufactured

by

Winmax

Japan

-

Superior

stopping

power

and

modulation

-

Consistent

performance

under

high

temperature

conditions

-

Compounds

available

for

street,

street

/

track,

and

dedicated

track

applications

-

PA015

/

PA035

caliper

uses

a

common

pad

shape,

with

compounds

readily

available

from

various

manufacturers

>AVAILABLE

PAD

COMPOUNDS

>MORE

INFO

REGARDING

THE

PAD

SHAPE

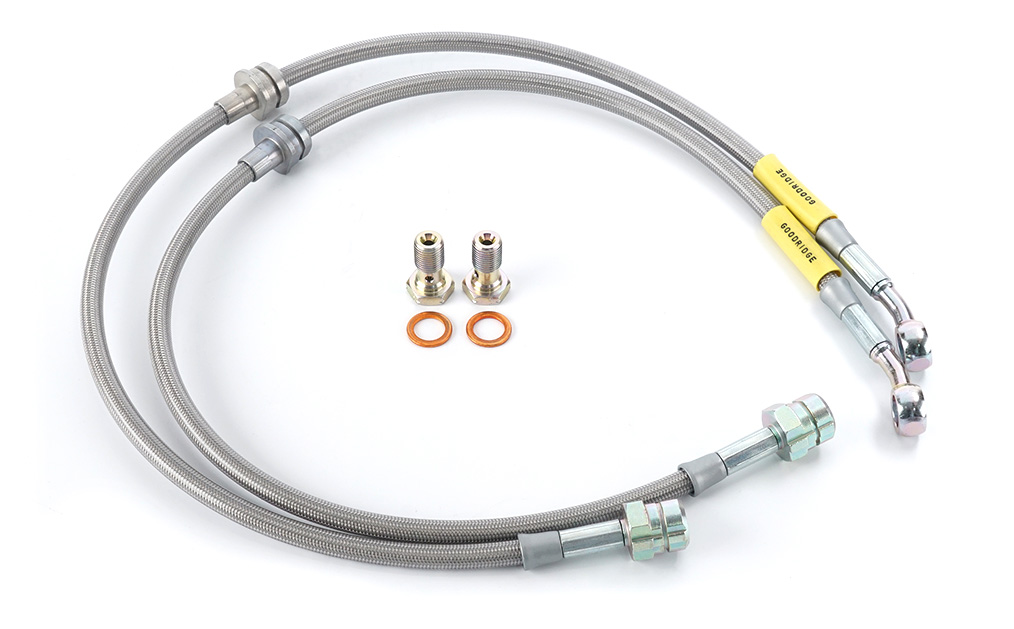

Goodridge

Stainless

Steel

Braided

Brake

Lines

-

Superior

durability.

Abrasion

and

corrosion

resistant

-

Allows

more

responsive

and

firmer

pedal

feel

<

Wheel

Fitment

Wheel

Fitment

Template

Download

(PDF):

343x32mm

/

355x32mm

/

378x36mm

> How

to

use

the

wheel

fitment

template

(PDF)

**343mm

brake

kits

generally

require

17"

or

larger

wheels,

355mm

brake

kits

generally

require

18"

or

larger

wheels,

while

378mm

brake

kits

generally

require

18"/19"

or

larger

wheels.

Fitment

varies

due

to

different

specs

/

wheel

design.

Verify

fitment

with

wheel

fitment

template.